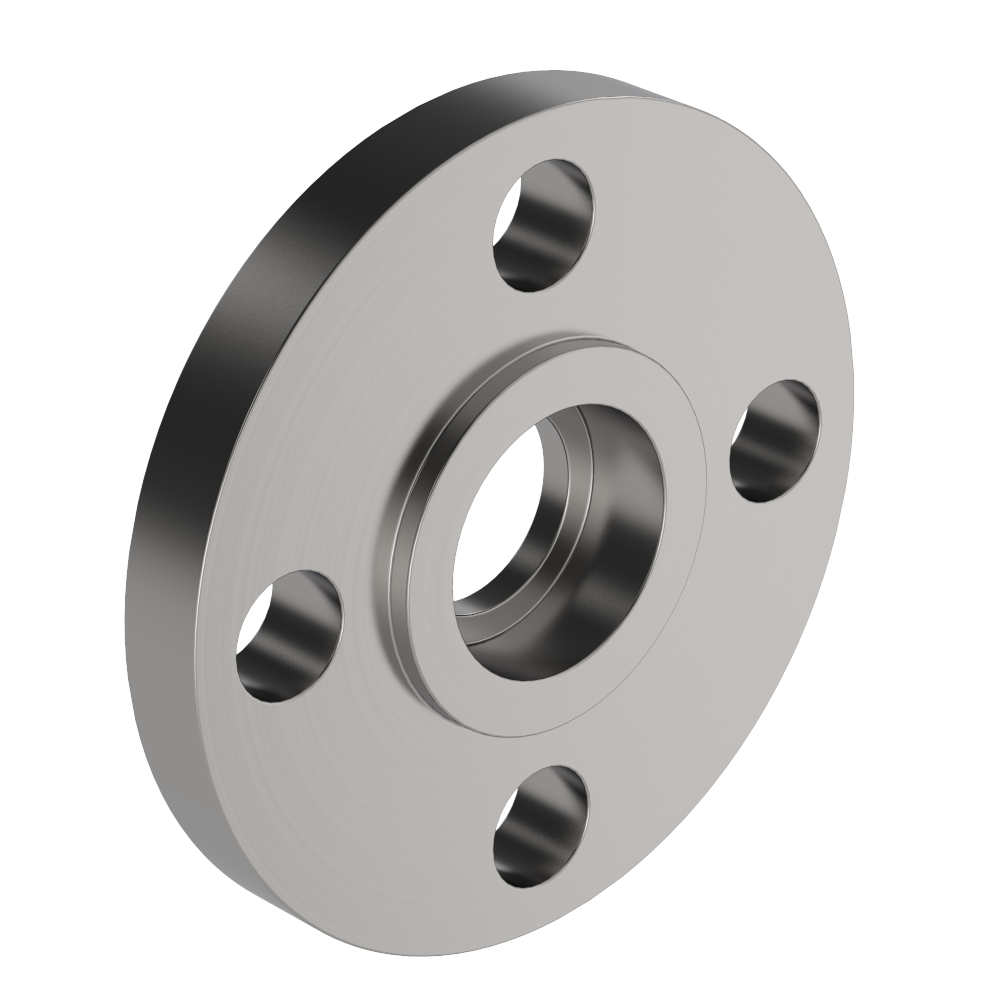

Alloy Steel A182 F5 Flange, ANSI B16.5 Alloy Steel F5 Socket Weld Flange, ASME SA182M Alloy Steel F5 Threaded Flange, ANSI B16.48 Alloy Steel 5Cr-1/2Mo WNRF Flange, BS4504 A182 F5 Chrome Moly Flange, Check SA 182 Gr F5 Steel Flanges, Alloy Steel A182 Grade F5 slip on Flanges Dimension

Alloy Steel F5 Flanges Specification

Specification: ASTM A182 / ASME SA182

Size: 1/2" to 48" NB

Dimensions Chart: ANSI/ASME B16.5, BS4504, BS 10,

B 16.47 Series A & B, B16.48, EN-1092, DIN, etc.

Dimension Standard: ANSI, ASME, BS, DIN, EN etc.

Type: Ring Joint Flange (RTJ), Flat Face Flange (FF),

Raised Face Flange (RF), Male and Female Flange (M & F),

Lap Joint Flange, Large and Small Tongue-and-Groove Flange (T & G)

Class: 150#, 300#, 600#, 900#, 1500#, 2500#,

PN6, PN10, PN16, PN25, PN40, PN64 etc.

Due to its remarkable mechanical features and strength when facing heat, corrosion, and wear, alloy steel is frequently used in different industrial processes. One exceptional example of an alloy steel flange is the ASTM A182 GR F5 flange. It is designed to be used effectively in extreme temperature and pressure environments.

The ASTM A182 GR F5 flange provides strength, resistance to oxidation and toughness due to a combination of chromium and molybdenum materials. In comparison to regular carbon steel flanges, it has more exceptional qualities. Thus, it is widely utilised in oil and gas, petrochemical, power generation, and chemical processing industries.

ASTM A182 GR F5 flange has qualities such as excellent tensile strength, and noteworthy resistance to rust and oxidation when subjected to higher temperatures. This flange type can tolerate temps up to 1100°C (2000°F), allowing it to be suitable for jobs involving extremes of heat. In addition, its effectiveness against corrosion means it is dependable when exposed to different sulphur and acidic solutions, along with hydrogen sulphide.

The ASTM A182 GR F5 flange also offers the benefit of being highly weldable. It can be welded using different traditional methods, permitting a less demanding production and installation. The flange comes in multiple dimensions and pressure ratings to fulfil the specific needs of any project.

Alloy Steel F5 Flanges Specifications

| Specifications | ASTM A182 / ASME SA182 |

|---|---|

| Size | 1/2" (15NB) to 48" (1200NB) |

| Standards | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Dimensions | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Pressure Ratings | Class 400, Class 150, Class 1500, Class 300, Class 900, Class 2500, Class 600 |

| Flange Face Type | Flate Face, Raised Face, Ring Type Joint |

| Coating/Surface Treatment | Yellow Transparent, Oil Black Paint, Anti-rust Paint, Cold and Hot Dip Galvanized, Zinc Plated. |

The ASTM A182 GR F5 flange has many applications in numerous sectors. It is regularly employed in pipelines, vessels containing pressure, boilers, and heat exchangers operating in high temperatures and pressures. Its dependability and sturdiness make it apt for well-connected joints to guarantee the integrity and safety of the whole system.

At our company, we pack Alloy Steel ASTM A182 GR F5 flanges to protect them during transportation. Each flange is wrapped with a protective covering to prevent damage or scratches. They are then securely packed in sturdy boxes, using appropriate cushioning materials to minimise any impact during handling. Our packaging process ensures that the flanges reach our customers in pristine condition, ready for immediate use.