Omaa Metal Sources We are one of the critical Manufacturer, Supplier and Exporter of Stainless Steel Socket Weld Unequal Tee. Shaped Socket Weld Fittings Unequal Tee are utilized positively related to ASME Pipe. On the off chance that you essentially utilize such a tee, by then it might cause the mishandle in work. Consequently, continually investigate encounters regarding the Forged Socket weld Unequal (Reducing) Tee by then purchase.

Socket Weld Unequal Tee,Socket Weld Unequal Tee Manufacturers, Socket Weld Unequal Tee Exporters, Socket Weld Unequal Tee Suppliers, Socket Weld Unequal Tee Stockists, Socket Weld Unequal Tee Manufacturers, Socket Weld Unequal Tee Exporters, Socket Weld Unequal Tee Suppliers, Socket Weld Unequal Tee Stockists.

Our Stainless Steel Socket Weld Reducing Tee is totally used to decrease transport lines, for example, 3/8″ to 1/4″ to help ice manufacturers and depicted out according to ASME guidelines. We pass on ASME B16.11 Reducing Tee, Socket Weld Reducing Tee and SS Forged Steel Socket weld Reducing Tees at put withdrew down rate contemplating reasonable master hours in India and sufficient deftly of five star ANSI B16.11 Forged Socket Weld Tee, most ideal circumstance, cost open in Mumbai, India.

Omaa Metal Sources, Our Carbon Steel Forged Socket Weld Unequal Tee Fittings are made by utilizing the remarkable assessment steel involving cutting edge strategies in consistence with mechanical quality rules. Our Stainless Steel Socket Weld Unequal Tee and Carbon Steel Forged Socket Weld Unequal Tee Fittings are made by utilizing the ordinary evaluation steel utilizing bleeding edge approachs in change with present day quality standards. Right when you utilize the Duplex Steel Socket weld Unequal Tee then you can see its highlights, for example, high check towards the ruinous climate and capacity to persevere through senseless weight identically as temperature. This tee when you analyze the market it is being proposed to you in a course of action of plans, shapes, size, and wraps up. Money related expert of Socket Weld Unequal Tee in India.

Composed to too give free starter of 3000LB Socket Weld Unequal Tee, We are having our Dealer and Distributor in Karnataka, Chennai, Ahmedabad, Tamil Nadu, Vadodara, Punjab, Kolhapur, Karnataka, Jaipur, Nagpur, Ghaziabad, Gujarat, Rajkot, Bhosari, Rajasthan, Uttar Pradesh, Faridabad, Chhattisgarh, Khopoli, Pune, Maharashtra, Bangalore, Madhya Pradesh, Kolkata, Delhi, Raipur, Gurgaon, Aurangabad, Ludhiana, Indore, West Bengal, Haryana. Call us for the Most relentless and Upgraded cost List of Socket Weld Forged Unequal Tees and Stainless Steel Socket Weld Reducing Tee.

Treated Steel Socket Weld Unequal Tee is such a fitting that is T spread out and is having two outlets, at the avocation behind 90ᵒ assemble as one with the mainline. SS Forged Steel Socket weld Reducing Tees is essentially used to interface pipelines with different lines at the 90ᵒ point with a line. The tee of fitting norm, examination, class, and type will serve solid execution and less mess up. Rules accessible for Forged Socket weld Unequal Tee are ASME B16.11/BS3799.

Socket Weld Unequal Tee Manufacturers in Mumbai, Socket Weld Unequal Tee Exporters in Mumbai, Socket Weld Unequal Tee Suppliers in Mumbai, Socket Weld Unequal Tee Stockists in Mumbai.

Specification of Socket Weld Unequal Tee

| Specifications | Forged Unequal Tee |

|---|---|

| Dimension Specification | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Unequal Tee Forged Fittings Thread | NPT, BSPT, BSPP |

| Unequal Tee FittingsType | DN15-DN1200 |

| End | Threaded, Welding, JIC |

| Unequal Tee Fittings Pressure Rating | Threaded end-2000lb/ 3000lb/ 6000lbs Unequal Tee |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom Unequal Tee |

| Size Range | 1/8" NB TO 4" NB |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| Unequal Tee Test Certificates |

EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Origin & Mills | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Key markets and industries for Unequal Tee Fittings |

|

| Application |

|

Material of Socket Weld Unequal Tees

| Carbon Steel Unequal Tee |

|

| Stainless Steel Socket weld Unequal Tee |

|

| Alloy Steel Unequal Tee |

|

| Titanium Unequal Tee |

|

| Inconel Unequal Tee |

|

| Copper Unequal Tee | T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910,C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500, C11600, C12000,C12200, C12300, TU1, TU2, C12500, C14200, C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800, C63020, C68700, C70400, C70600, C70620, C71000, C71500, C71520, C71640, etc |

| Copper Nickel Unequal Tee | Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Brass Unequal Tee | 3602 / 2604 / H59 / H62 / etc. |

| Hastelloy Unequal Tee | Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X |

| Monel Unequal Tee | Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Alloy 20 Unequal Tee | Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Aluminium Unequal Tee | 5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Nickel Unequal Tee | Nickel 200, Nickel 201 |

| Duplex Unequal Tee | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Super Duplex Unequal Tee | S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Incoloy Unequal Tee | Incoloy 800, Incoloy 800H, Incoloy 800HT (UNS N08800), Incoloy 825 (UNS N08825) |

| 254 Smo Unequal Tee | SMO 254/6Mo, UNS S31254, DIN 1.4547 |

| Nimonic Unequal Tee | Nimonic 75, Nimonic 80A, Nimonic 90 |

| Other Unequal Tee material | Tin bronze, Alumunum bronze, Lead bronze |

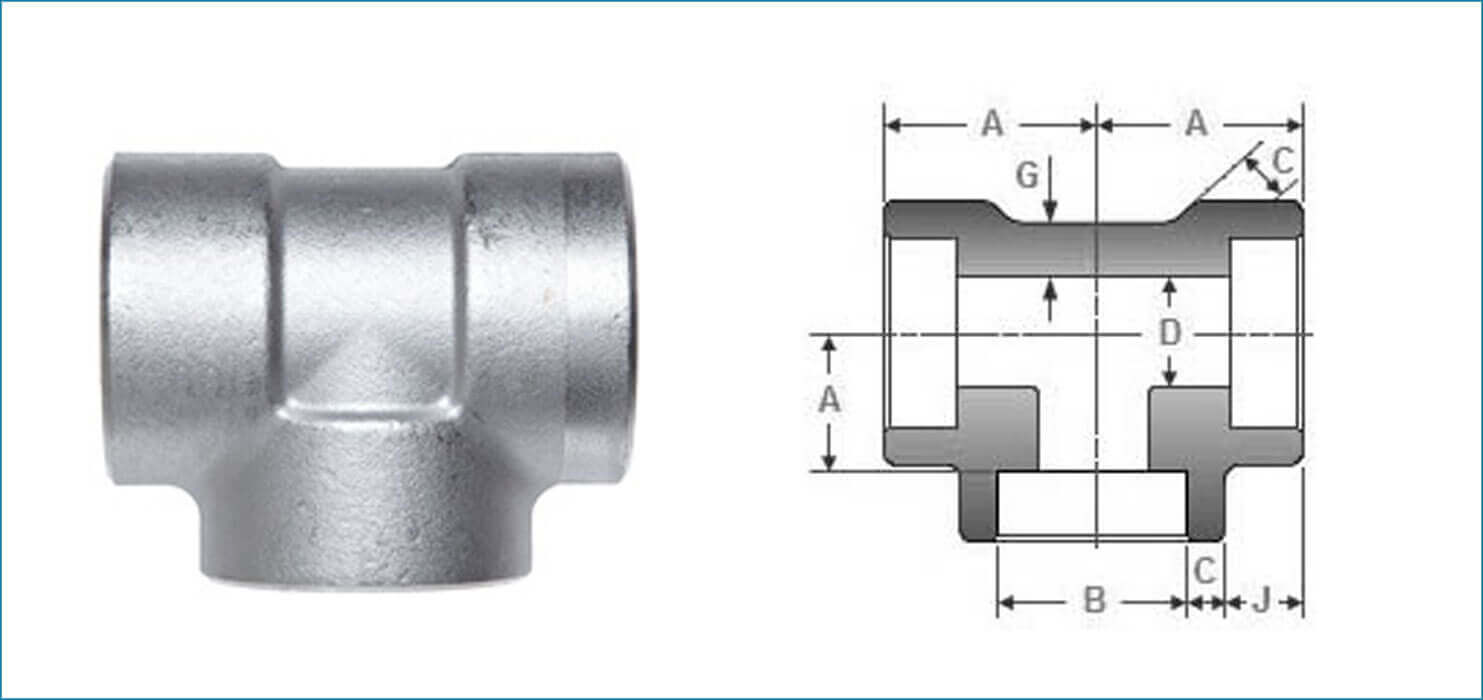

Dimensions of Socket weld Unequal Tee

Dimensions NPS 1/2 to 4 – 90°/45° – Class 3000

| NPS |

Socket Bore |

Depth Socket |

Bore dia |

Socket WT |

Body WT |

Center to bottom of socket |

| B | J | D | C | G | A | |

| 1/2 |

21.95 21.70 |

10 |

16.6 15 |

4.65 4.10 |

3.75 | 15.5 |

| 3/4 |

27.30 27.05 |

13 |

21.7 20.2 |

4.90 4.25 |

3.90 | 19.5 |

| 1 |

34.05 33.80 |

13 |

27.4 25.9 |

5.70 5.00 |

4.55 | 22 |

| 1.1/4 |

42.80 42.55 |

13 |

35.8 34.3 |

6.05 5.30 |

4.85 | 27 |

| 1.1/2 |

48.90 48.65 |

13 |

41.7 40.1 |

6.35 5.55 |

5.10 | 32 |

| 2 |

61.35 61.10 |

16 |

53.5 51.7 |

6.95 6.05 |

5.55 | 38 |

| 2.1/2 |

74.20 73.80 |

16 |

64.2 61.2 |

8.75 7.65 |

7.00 | 41.5 |

| 3 |

90.15 89.80 |

16 |

79.5 46.4 |

9.50 8.30 |

7.60 | 57.5 |

| 4 |

115.80 115.45 |

19 |

103.8 100.7 |

10.70 9.35 |

8.55 | 66.5 |

| NPS | B | J | D | C | G | A |

|

Socket Bore |

Depth Socket |

Bore dia |

Socket WT |

Body WT |

Center to bottom of socket |

Dimensions NPS 1/2 to 2 – 90°/45° – Class 6000

| NPS |

Socket Bore |

Depth Socket |

Bore dia |

Socket WT |

Body WT |

Center to bottom of socket |

| B | J | D | C | G | A | |

| 1/2 |

21.95 21.70 |

10 |

12.5 11 |

5.95 5.20 |

4.80 | 19.5 |

| 3/4 |

27.30 27.05 |

13 |

16.3 14.8 |

6.95 6.05 |

5.55 | 22.5 |

| 1 |

34.05 33.80 |

13 |

21.5 19.9 |

7.90 6.95 |

6.35 | 27 |

| 1.1/4 |

42.80 42.55 |

13 |

30.2 28.7 |

7.90 6.95 |

6.35 | 32 |

| 1.1/2 |

48.90 48.65 |

13 |

34.7 33.2 |

8.90 7.80 |

7.15 | 38 |

| 2 |

61.35 61.10 |

16 |

43.6 42.1 |

10.90 9.50 |

8.75 | 41 |

| NPS | B | J | D | C | G | A |

|

Socket Bore |

Depth Socket |

Bore dia |

Socket WT |

Body WT |

Center to bottom of socket |

General notes:

- Dimensions are in millimeters unless otherwise indicated.

- Socket Bore (B) – Maximum and minimum dimensions.

- Bore Diameter (D) – Maximum and minimum dimensions.

- Socket wall thickness – (C) – Average of Socket wall thickness.

-

Dimensional tolerances center to bottom of socket – (A)

NPS 1/2 and NPS 3/4 = +/- 1.5 mm

NPS 1 to NPS 2 = +/- 2 mm

NPS 2.1/2 to NPS 4 = +/- 2.5 mm