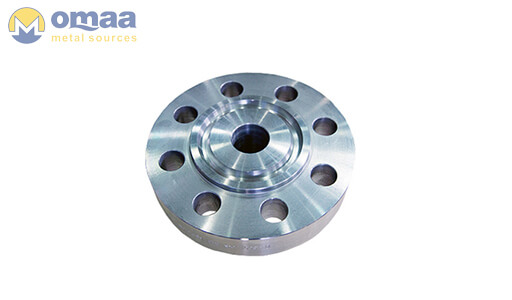

Manufacturer and exporter of UNS S32750 ASTM A182 F53 Pipe Flange, check UNS S32750 Blind Flange Manufacturer, ASTM A182 F55 UNS S32760 Flange, UNS S32760 F55 Threaded Flange at best price

Super Duplex F53 Flange Specification

Specification: ASTM A182 / ASME SA182

Size: 1/2" (15 NB) to 48" (1200NB)

JIS: 5K, 10K, 16K, 20K, 30K, 40K, 63K

Dimension Standard: ANSI, ASME, BS, DIN, EN etc.

Type: Ring Joint Flange (RTJ), Flat Face Flange (FF),

Raised Face Flange (RF), Male and Female Flange (M & F),

Lap Joint Flange, Large and Small Tongue-and-Groove Flange (T & G)

Pressure rating: 150#, 300#, 600#, 900#, 1500#, 2500#,

PN6, PN10, PN16, PN25, PN40, PN64 etc.

Super Duplex S32750 and S32760 are two popular grades of stainless steel known for their exceptional properties. These grades belong to the super duplex stainless steel family, which combines the advantages of austenitic and ferritic stainless steel. Let's delve into the properties of each grade individually.

Super Duplex S32750, also known as SAF 2507, offers a high level of corrosion resistance, making it suitable for demanding environments such as offshore oil and gas production, chemical processing, and marine applications. It resists chloride-induced stress corrosion cracking, pitting, and crevice corrosion. S32750 exhibits a higher strength than standard duplex stainless steels, with a minimum yield strength of 550 MPa (megapascals) and a minimum tensile strength of 795 MPa. This grade also maintains good toughness, even at low temperatures.

On the other hand, Super Duplex S32760, also known as Zeron 100 or SAF 2760, possesses even higher corrosion resistance than S32750. It is particularly suitable for environments containing chlorides, sulfuric acid, and seawater. S32760 exhibits resistance to corrosion, including pitting and crevice corrosion, compared to S32750. It also offers higher mechanical strength, with a minimum yield strength of 550 MPa and a minimum tensile strength of 750 MPa.

S32750 and S32760 exhibit good weldability, allowing for easy fabrication and installation. They have excellent thermal conductivity and low thermal expansion, which is advantageous for heat exchanger applications. These grades also demonstrate high resistance to erosion, making them suitable for applications involving abrasive media.

Incoloy 825 Flanges Specifications

| Flanges Size Chart | DN10~DN5000 1/2 inch (15 Nominal Bore) - 48 inch (1200 Nominal Bore) |

|---|---|

| Pressure Rating ANSI Flanges | 150LBS, 900LBS, 1500LBS, 600LBS, 2500LBS 300LBS, |

| in DIN Flanges Pressure Calculation | PN10, PN6, PN25, PN16, PN64, PN40/ 10Bar, 6Bar, 25Bar, 16Bar, 40Bar |

| Flanges JIS | 30K, 20K, 5K, 10K, 63K, 40K, 16K |

| SORF Flanges Standards | B16.47, BS 10, B16.48, BS4504, DIN, EN-1092, ANSI / BS / ASME / EN / DIN Flanges, ASME/ANSI 16.36/B16.5/16.47B/16.47A, MSS S44, GOST Flanges, JISB2220, ISO70051, API7S-15, BS1560-3.1, API605, API7S-43, EN1092, ANSI/ASME B16.5 |

| basic types of ASTM A182 F53 Flange | Threaded / Plate/ Forged / Screwed |

| Flanges UNI | 16 Bar, 40 Bar, 10 Bar, 25 Bar, 6 Bar |

| Flanges EN | 6 Bar, 40 Bar, 10 Bar, 25 Bar, 16 Bar |

| Coating on surface | Hot and Cold Dip Galvanized, Oil Black Paint, Yellow Transparent, Zinc Plated, Anti-rust Paint |

| ASTM A182 F53 Flange Face and Connect Type | SMF, Ring Type Joint (RTJ), Raised Face (RF), Lap-Joint Face (LJF), Large / Small Tongue & Groove, LMF, Flat Face (FF) |

| Flanges Test | , Hydrostatic testing machine, Direct-reading Spectrograph, Magnetic particle and X-ray and UI trasonic flaw detector |

| Flanges Equipment | Sand-blasting and Pushing/E lectric bevelling machine, Press and Bending machine etc |

| technique of Flanges Production |

|

| Origin of Flanges | Korean/ Indian / USA / West Europe /Japan |

| custom Supply |

customer requirement

ANSI, AS, DIN , JIS and BS |

| Manufacturer of ASTM A182 F53 Flange |

NFE, SABS, ANSI, AS2129, BS, JIS, AWWA, GOST, DIN,

EN, UNI etc.

|

| Flanges Export to | Abu Dhabi , Gimhae-si, Pimpri-Chinchwad, Gurgaon, Sydney, Riyadh, Ahmedabad, Mexico, Surat, Muscat, Kanpur, Bangalore, Khobar, Courbevoie, Perth, Melbourne, Baroda, Ankara, Rajkot, Istanbul, Indore, Kolkata, Bengaluru, Ahvaz, Mumbai, Nagpur, Kuwait, Coimbatore, Lagos, Montreal, Jamshedpur, Damilimeteram, Ernakulam, Calgary, Gujarat, Santiago, Tehran, Chennai, Noida, Hyderabad, Thiruvananthapuram, Vadodara, Howrah, Tau, Ranchi, Caracas, Bogota, Janeiro, Manama, India, Ludhiana, London, Karachi, New Delhi, Port-of-Spain |

Both grades feature a combination of chromium, molybdenum, nickel, and nitrogen, giving them specialised protection against rusting. Furthermore, their capacity for flexibility and durability further enhances their reliability, avoiding breakage.

At our company, we prioritise the protection of Super Duplex S32750 and S32760 grades when packing, using sturdy, moisture-resistant containers to prevent any harm or corrosion. Additionally, appropriate padding and cushioning are utilised to ensure the secure transportation of the steel and guard against marks or dents. Our packaging meets the necessary industry regulations, preserving the quality of the product until it reaches its destination.