Exporters of BS 10 PN 10 Flanges, Ready Stock of BS 10 Forged Flange, BS 10 Table D Flanges, Check Sizes And Dimensions Of BS 10 Socket Weld Flange.

BS 10 flanges Specification

Size: 1/2" (15 NB) to 48" (1200NB) DN10~DN5000

Schedule: SCH10, SCH 40, SCH 80, SCH 160 To SCH XXS

Dimension Standard: ANSI/ASME B16.5, B 16.47 Series A & B,

B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Type: Ring Joint Flange (RTJ), Flat Face Flange (FF),

Raised Face Flange (RF), Male and Female Flange (M & F),

Lap Joint Flange, Large and Small Tongue-and-Groove Flange (T & G)

Pressure rating: 150#, 300#, 600#, 900#, 1500#, 2500#,

PN6, PN10, PN16, PN25, PN40, PN64 etc.

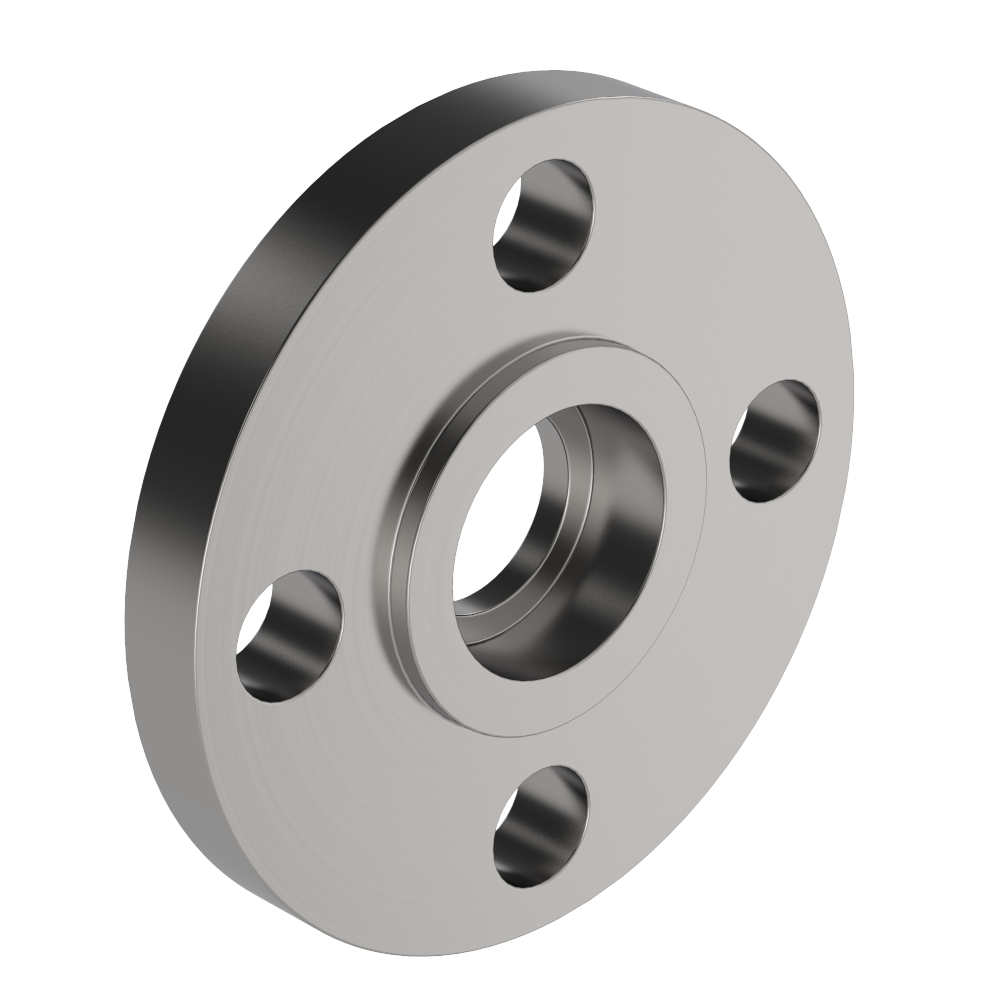

BS 10 flanges, also known as British Standard flanges, are widely used in various industries for connecting pipes, valves, and other equipment in piping systems. These flanges adhere to the British Standard BS 10 specifications, which outline their dimensions, materials, and other relevant properties. Understanding the properties of BS 10 flanges is crucial for ensuring the integrity and functionality of the piping system.

BS 10 flanges possess another remarkable attribute: suitability for various operating conditions. These flanges can be manufactured by particular temperature and pressure needs, authorising them to process a range of gases and liquids. This multifaceted nature renders BS 10 flanges well-suited for different industrial applications, which include the oil and gas sector, petrochemicals, power generation, and water treatment.

BS 10 flanges are distinguished by their bolt-hole pattern, which creates a secure, sealed connection between the flange and connected parts. The bolt holes are accurately placed, making for simple alignment during assembly and upkeep. These flanges sometimes include a gasket seal to further ensure a tight seal.

BS 10 Flanges Specifications

| Stainless Steel BS10 Table E Pipe Flange Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K A182 F304L BS10 Table E Plate Flanges |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar BS10 Table E weld neck Flanges |

| A182 F304L BS10 Table E Plate Flanges Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 BS10 Table E Slip on Flange |

| Most common types of BS10 Table E Flanges | Forged / Threaded / Screwed / Plate |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar Stainless steel table e flange |

| BS10 Table E Slip on Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS BS10 table e threaded flange |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Stainless steel table e flange Uses & application |

|

BS 10 flanges are convenient and straightforward to install and maintain. These flanges can simply be secured with bolts or welded onto pipes or machinery, simplifying the process. Furthermore, when dismantling or replacement is essential, the flanges can quickly be removed and put back in without significantly causing delays.